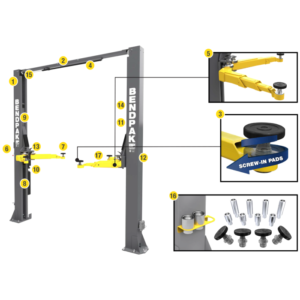

BendPak 10APX-181 / 10,000‐lb. Capacity / Adaptable Clearfloor / Adjustable Width / HIGH-RISE

$6,195.00

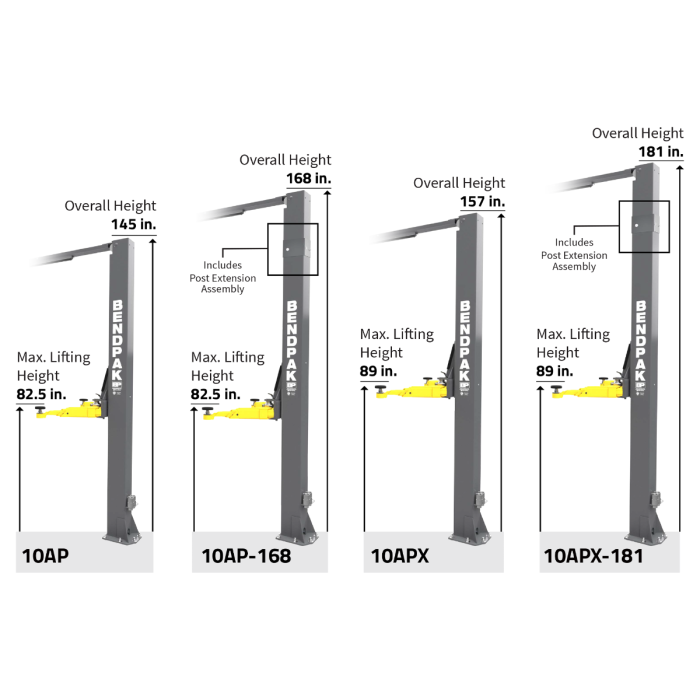

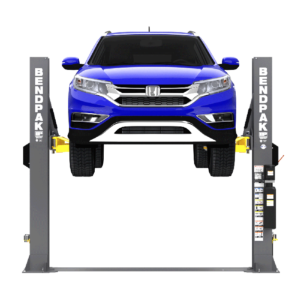

he 10AP Series is meticulously crafted to future-proof your shop, incorporating all the essential attributes for optimal vehicle servicing. This groundbreaking lift effortlessly accommodates Electric Vehicles and seamlessly transitions between symmetrical and asymmetrical configurations. The 10APX-181 high-rise lift sports an overhead beam height of 181” to accommodate high-roof cargo vans.

10APX-181: Maximize Comfort and Performance

Introducing the 10APX-181, engineered to cater to mechanics who spend their days in challenging positions. Say goodbye to discomfort and hello to a premium workspace that accommodates the best equipment for the job. For those tackling larger vehicles, the 10APX-181 is your go-to solution. Equipped with the same lifting height and enhanced by a towering 181” overhead beam, this lift is your answer for high-roof cargo vans. True to the 10AP series, these lifts feature a robust 10,000-lb. lifting capacity, Low-Pro arms, Bi-Metric™ arms, and much more!

Reaching New Heights in Automotive Lifting

As auto repair shops strive to stay ahead of the technological curve, BendPak’s all-new AP series of two-post lifts sets a groundbreaking standard. This series ingeniously melds the finest traits from contemporary two-post lifts into an entirely original car lift engineering concept. The outcome is a lift that stands unparalleled in the market, meticulously crafted for rugged use, heavy loads, and unwavering operator safety and efficiency.

10AP Series: Versatile Convenience at its Best

The AP series brings forth the convenience of both wide and narrow installation options, all rolled into a single, customizable package. These lifts are not only sturdy and secure but also equipped with our advanced Bi-Metric™ arms, capable of seamlessly performing symmetric and asymmetric lifting. Combining simplicity with sophistication, this intelligent lift design ensures minimized service and maintenance expenses, delivering heightened productivity and lowered operating costs.

Advancing Safety Through Innovation

The automotive industry has consistently embraced emerging technologies, reshaping the way vehicles operate. With electric vehicles (EVs) gaining momentum, BendPak’s engineers have developed the 10AP series with a focus on enhanced operator safety. As EVs grow larger in size due to battery reinforcements, these lifts offer the ideal solution for servicing them efficiently, including trucks, vans, and sports cars. High tensile-strength steels, low-profile arms, and meticulously designed swing arms reflect our commitment to safety-critical enhancements, empowering technicians to tackle heavier EVs with confidence.

Empowering the Future of EV Service

The rise of electric vehicles comes with a demand for lifting solutions that can safely accommodate their weight. BendPak’s AP series addresses this need head-on. From reinforced construction to purposeful design features, these lifts are engineered to match the increased weight of EVs, allowing for efficient service on trucks, vans, and more. The low-profile arms and expanded column spacing provide exceptional under-car access, while the sturdy swing arms with greater telescoping movement offer precise lifting support for various EV models.

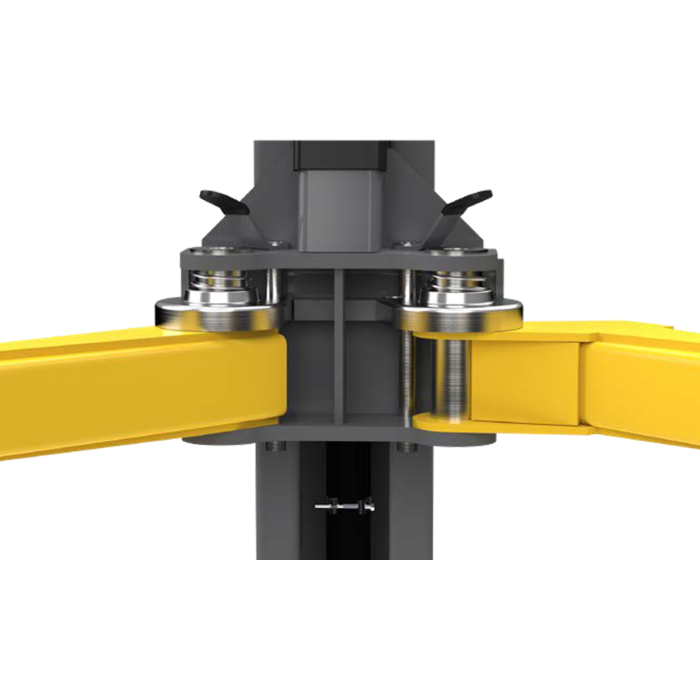

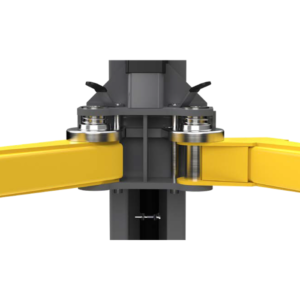

Revolutionary Automatic Swing Arm Restraint System

Traditional swing arm restraints have met their match in the AP series. A standout feature is the revolutionary Automatic Swing Arm Restraint System (ASARS), engineered to endure the elevated forces exerted during vehicle service. This patented system, constructed with heavily forged steel, locks lift arms securely in place with an impressive load-holding force of over 2000 pounds. The result is unmatched stability, preventing unintended swing-arm movement during lift usage and vehicle service operations.

Precision Redefined with Triple-Telescoping Nested Swing Arms

BendPak’s patented triple-telescoping swing arms redefine precision lifting. These innovative arms stand apart from traditional designs by offering greater retraction and extension capabilities. The patented nesting feature enables seamless inner sliding arm movement, eliminating hindrances and ensuring maximum efficiency in vehicle lifting.

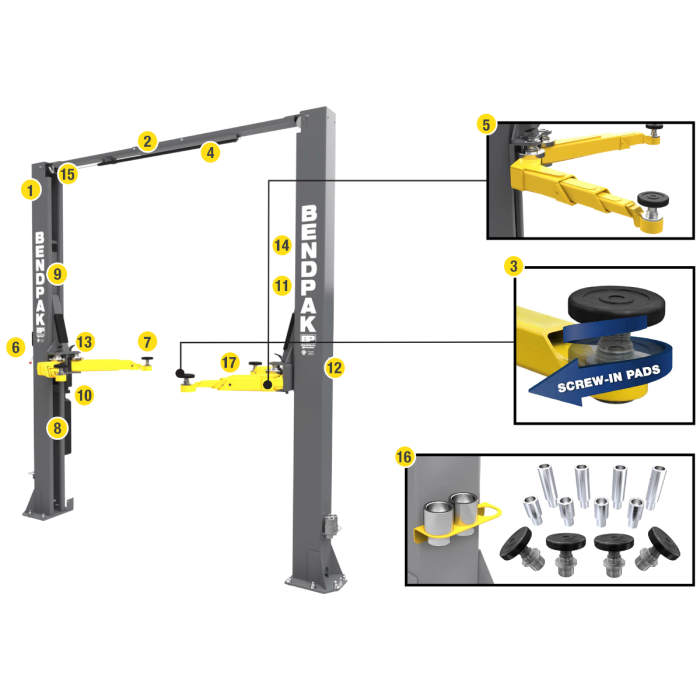

Low-Pro™: Where Versatility Meets Performance

Our exclusive Low-Pro™ swing arms redefine versatility, featuring telescoping channels with a shorter profile and dropped-end pad receivers. These arms are engineered for optimal under-car access on lowered chassis-height vehicles. The design minimizes the risk of damage to vehicle side skirts, running boards, and ground effects, while stackable adapters and spin-up screw pads provide secure vertical pad placement.

Customizable Precision with Screw Pads and Adapters

Experience flawless lifting alignment with OPTIONAL double-telescoping screw adapters, fortified with resilient polyurethane pads. These adapters ensure level lifting in all conditions, enhancing technician safety. The 2.5″ and 5″ stackable adapters further optimize vertical pad placement for secure vehicle support.

Safety and Efficiency Harmonized with Innovative Lock System

BendPak’s patented automatic safety lock system redefines safety and efficiency. Designed for automatic engagement during lift rising operations, this system also boasts an ergonomic single-point release for effortless lock disengagement during lift descent. Simplifying the operator’s role, this system enhances overall safety and workflow.

Unleash Flexibility with BI-METRIC™ Swing Arms

Uniquely designed BI-METRIC™ adaptable swing arms offer exceptional flexibility. These arms empower users to configure their lifts symmetrically or asymmetrically, without the need for arm switching. The 2-in-1 design accelerates vehicle servicing, enabling technicians to work more efficiently than ever before.

Upgrade Your Service Standards with the AP Series

Experience a paradigm shift in automotive lifting with BendPak’s AP series. These lifts embody innovation, safety, and precision, delivering an unparalleled experience for auto repair shops. Equip your shop with the ultimate lifting solution and witness the transformation in efficiency and performance.

- Durable powder coat finish

- Expandable top beam accommodates wide or narrow drive-thru configurations

- Double-telescoping screw pads offer increased versatility

- Padded overhead safety shutoff bar

- Exclusive Bi-Metric™ arm design for more versatile arm positioning

- Single-point safety release

- Drop-end arms provide a lower pad height

- Dual hydraulic direct-drive cylinders

- Electric / hydraulic HVLP power system

- Self-lubricating dura-glide UHMW polyethylene bearing system

- Safety locks in each column spaced every 3″

- Automatic arm restraints withstand over 2000-pounds of side force

- Heavy-duty 1/2″ aircraft-quality equalizer cables

- Oversized cable sheave diameter reduces cable fatigue

- Four triple-telescoping arms

- ALI certified

- Lifting Capacity

- 10,000 lbs. (4,536 kg)

RISE

- A.Rise

- 75″ (1,905 mm)

- D.Min Height + Pad

- 4″ (102 mm)

- Time to Full Rise

- 45 Seconds

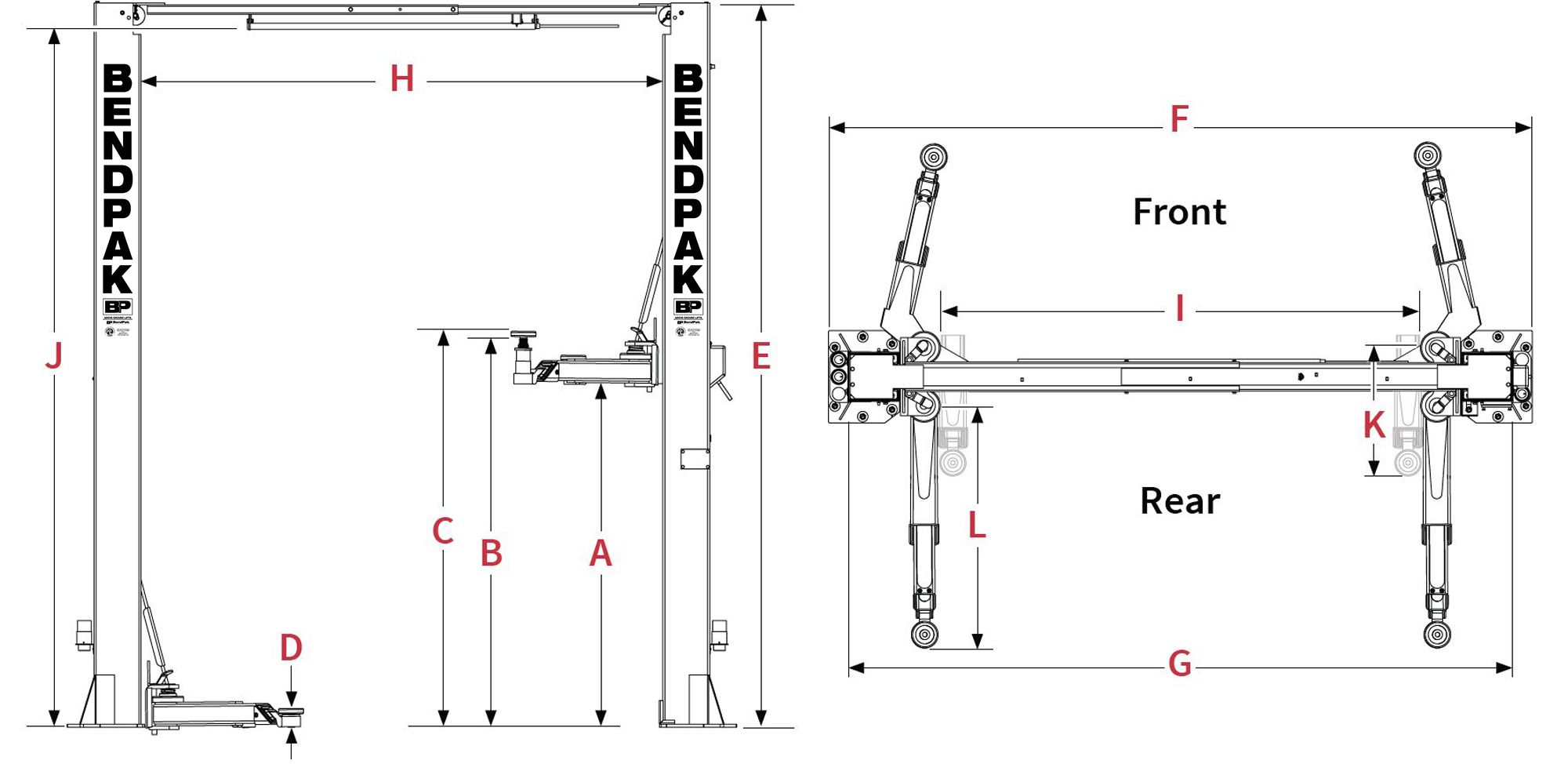

OUTSIDE DIMENSIONS

- E.Height Overall

- 181″ (4,597 mm)

- F.Width Overall

- 135″ (3,429 mm) or 145″ (3,683 mm)

- G.Outside Columns

- 127″ (3,226 mm) or 137″ (3,480 mm)

INSIDE DIMENSIONS

- H.inside Columns

- 108.25″ (2,750 mm) or 118.25″ (3,004 mm)

- I.Drive-Thru Clearance

- 92″ (2,337 mm) or 102″ (2,591 mm)

- J.floor to overhead switch

- 175.5″ (4,458 mm)

ARMS & PADS

- K.Front arm reach (MIN)

- 22″ (559 mm)

- K.Front arm reach (MAX)

- 47.5″ (1,207 mm)

- L.Rear arm reach (MIN)

- 29.5″ (749 mm)

- L.Rear arm reach (MAX)

- 57″ (1,448 mm)

- max load per arm

- 2500 lbs (1,134 kg)

- noise

- <70 dB

SHIPPING

- Shipping Dimensions

- 162″ x 24″ x 30″ (4,115mm x 610mm x 762mm )

- Weight

- 1902.00

Be the first to review “BendPak 10APX-181 / 10,000‐lb. Capacity / Adaptable Clearfloor / Adjustable Width / HIGH-RISE” Cancel reply

Related products

2-Post Lifts

Reviews

There are no reviews yet.